In the competitive world of manufacturing, precision and efficiency are paramount. Traditional machining methods often fall short, leading to costly errors and wasted materials. 5 Axis CNC machining offers a solution, providing unparalleled accuracy and versatility. let’s explores how this advanced technology can revolutionize your production process.

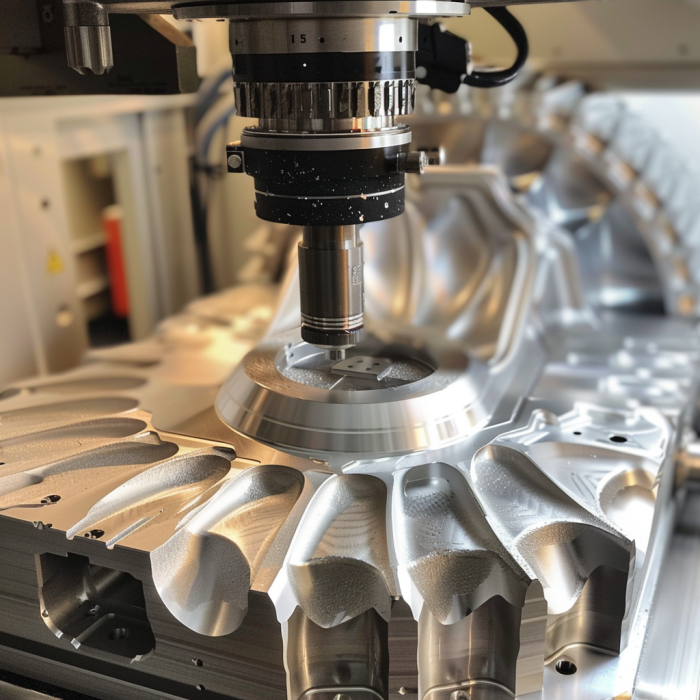

5 Axis CNC machining involves the use of computer numerical control to move a tool or part across five different axes simultaneously. This method allows for the creation of complex shapes and precise details that are difficult to achieve with traditional 3-axis machines, enhancing production capabilities and product quality.

To understand why 5 Axis CNC machining stands out, let’s delve into its applications, benefits, and challenges.

What is 5 Axis CNC Machining?

5 Axis CNC machining is an advanced form of CNC (Computer Numerical Control) machining where tools or parts can move simultaneously along five different axes. These axes include the typical X, Y, and Z axes used in 3-axis machining, plus two additional rotational axes (A and B). which allows for the machining of complex shapes and details that would be challenging or impossible with fewer axes.

Historically, CNC machining has evolved from simple 2-axis machines to the sophisticated 5-axis machines we see today. This evolution has enabled manufacturers to produce more intricate and precise parts, significantly improving the quality and performance of finished products.

Benefits of 5 Axis CNC Machining

Increased Precision and Accuracy

5 Axis CNC machining offers unparalleled precision and accuracy, enabling the production of parts with tight tolerances and complex geometries. This level of precision reduces the need for manual finishing and ensures consistent quality.

Ability to Machine Complex Shapes in a Single Setup

With 5 Axis CNC machining, complex shapes can be machined in a single setup, eliminating the need for multiple setups and reducing the risk of errors. This capability improves efficiency and reduces production time.

Improved Surface Finish

The advanced capabilities of 5 Axis CNC machines result in superior surface finishes, reducing the need for additional finishing processes. This benefit is particularly important for industries like aerospace and medical, where surface quality is critical.

Enhanced Flexibility and Reduced Production Time

5 Axis CNC machining provides greater flexibility in manufacturing processes, allowing for the efficient production of a wide variety of parts. This flexibility reduces production time and allows for faster response to market demands.

Challenges of 5 Axis CNC Machining

Higher Initial Setup and Maintenance Costs

Investing in 5 Axis CNC machines requires a significant initial investment. Additionally, maintenance costs can be higher due to the complexity of the machinery. However, the benefits often outweigh these costs in the long run.

Requires Skilled Operators and Programmers

Operating and programming 5 Axis CNC machines requires specialized skills and knowledge. Training and retaining skilled personnel can be a challenge for manufacturers.

Complexity in Programming and Operation

The complexity of 5 Axis CNC machining can make programming and operation more challenging compared to traditional 3-axis machines. Manufacturers must invest in advanced software and training to maximize the benefits of this technology.

Potential for Increased Wear and Tear on Machinery

The increased complexity and precision of 5 Axis CNC machines can lead to greater wear and tear on the equipment. Regular maintenance and careful operation are essential to ensure the longevity and reliability of the machinery.

Applications of 5 Axis CNC Machining

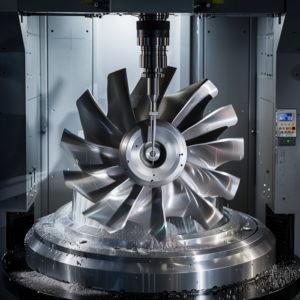

Aerospace

In the aerospace industry, precision is critical. 5 Axis CNC machining is used to manufacture complex components such as turbine blades, engine parts, and structural components. The ability to machine intricate geometries with high precision ensures that parts meet stringent safety and performance standards.

Automotive

The automotive industry benefits from 5 Axis CNC machining through the production of complex parts like transmission components, engine blocks, and custom parts for high-performance vehicles. This technology allows for the efficient production of parts with tight tolerances, enhancing vehicle performance and reliability.

Medical

In the medical field, 5 Axis CNC machining is used to create customized implants, prosthetics, and surgical instruments. The precision and accuracy of 5 Axis machining ensure that medical devices fit perfectly and perform reliably, improving patient outcomes.

Energy

The energy sector uses 5 Axis CNC machining to manufacture components for wind turbines, oil and gas exploration equipment, and other energy systems. The ability to produce large, complex parts with high precision is essential for the reliability and efficiency of energy infrastructure.

Incorporating 5 Axis CNC machining into your production process can lead to significant improvements in efficiency and product quality. By understanding its applications, benefits, and challenges, you can make informed decisions about integrating this advanced technology into your operations. Whether you are in the aerospace, automotive, medical, or energy industry, 5 Axis CNC machining offers the precision and versatility needed to stay competitive in today’s market.