Industrial & Manufacturing

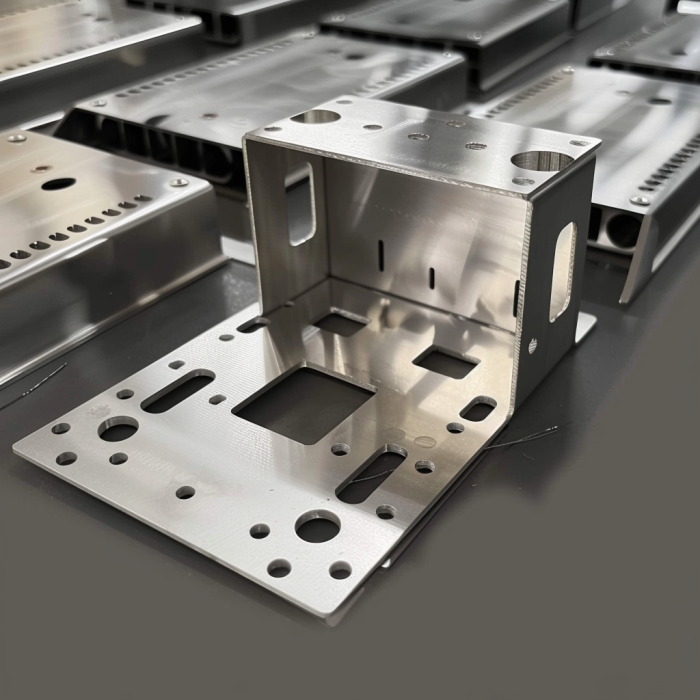

We adhere to DIN-2768-1-fine tolerances for metal parts , ensuring precision across materials. To best address the intricacies of your project’s geometry and material, our engineers are at your service for expert consultations.”

“Sheet metal fabrication encompasses a variety of manufacturing techniques aimed at transforming sheet metal stock into operational components. This metal typically ranges in thickness from 0.006 to 0.25 inches

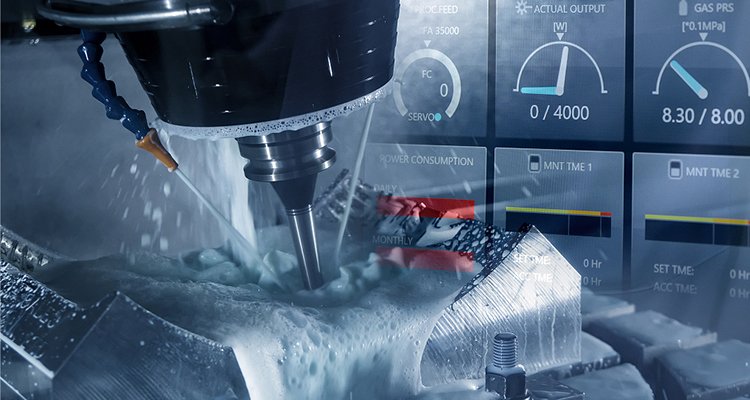

Swiss machining’s advanced CNC capabilities, with multiple axes and a guide bushing design, enable faster, more precise production of complex, intricate parts compared to traditional machining. This method’s superior precision, reduced deflection, and improved repeatability make it a preferred choice for manufacturing small components across diverse industries like aerospace, medical, and automotive.

CNC prototype services provide a rapid and flexible solution for producing custom parts, allowing designers to quickly test and iterate on new product designs. and a wide selection of materials to deliver high-precision prototypes with tight tolerances, while also offering design for manufacturability support and quality assurance certifications to meet the needs of diverse industries

CNC parts quality assurance involves thorough inspections at every stage, from materials to final checks, ensuring precision and compliance with standards. Choosing the right CNC machine, adhering to quality system ISO 9001:2018 . Continuous data analysis and calibration enhance parts quality assurance

Surface finish encompasses the attributes of a surface, such as its roughness, waviness, and orientation, all of which influence aspects like friction, durability, and visual quality. This finish can be tailored through diverse techniques to enhance certain features, including adhesion, resistance to corrosion, or aesthetic value.

Who we are

KACHI- CUSTOM MACHINING PARTNER

Kachi, established in 2013 by engineer Fu, began with humble beginnings on a manual machine. Through years of dedication and growth, we’ve expanded our capabilities with state-of-the-art equipment from renowned international brands. We pride ourselves on recruiting and nurturing talented, educated young graduates, training them to excel in projects that meet global standards. Our founder’s vision is to become a trusted machining partner for everyone, from engineering teams to major brands, transforming your ideas into tangible products. At Kachi, we don’t just focus on crafting exceptional parts; we’re committed to being outstanding partners. Our diverse team of engineers and managers from around the world is dedicated to guiding you seamlessly through the manufacturing process, ensuring the success of your projec

Steps of custmize your parts

tell us your requirements or send your designs for evaluation

work out your projects budgets base on drawings and projects team comments

Ensure every project's requirements are meticulously met, your custom parts are efficiently produced, and everything is delivered directly to your doorstep

our site

Located in the heart of China’s industrial zone, Kachi Machining’s head office located in centre of Dongguan.Our expert team works closely with our engineer ensuring every project meets the standards of excellence

By incorporating lean manufacturing principles and continuous improvement methodologies, we not only enhance our operational efficiencies but also minimize waste, contributing to a more sustainable manufacturing environment. This commitment to excellence and sustainability ensures that every part from Kachi is manufactured with strict quality system, tailored to the specific needs of our clients.

Our team of highly skilled engineers, based out of our state-of-the-art facility in China, is dedicated to pushing the boundaries of precision engineering to meet and exceed the expectations.Our engineering team thrives on challenges. Armed with advanced degrees and deep industry experience, our professionals bring a blend of innovation, expertise, and meticulous attention to detail to every project.

At Kachi, we believe in investing in the best to produce the best. Our reliance on international brand equipment is a testament to this philosophy, enabling us to offer clients exceptional quality, rapid turnaround times, and customizable solutions that drive innovation and operational excellence.By incorporating these advanced machines into our workflow, Kachi Machining achieves superior efficiency, accuracy, and speed, distinguishing our services in the competitive global market.

We understand that quality is not just about the final product but also about the processes that create it. That’s why our quality system encompasses every stage of production, from raw material selection through to final inspection and delivery. Our proactive approach to quality management includes regular audits, employee training, and a culture of quality that permeates every aspect of our operations

Fermentum ornare vel vestibulum suscipit sed magna efficitur.

Our samples are not just prototypes; they are a showcase of Kachi’s capabilities in delivering top-quality CNC machining parts. Each sample is produced using the same high-end equipment, materials, and attention to detail that characterize our full production runs. This ensures that you receive a true representation of our work, allowing for thorough evaluation and confidence in the final product.

Common Questions

Most Popular Questions.

we prepare our customer typical quesions, please check by right side

we can make metals like aluminum, steel, stainless steel, brass, and plastics and so on to ensure your specific material requirements can be met.

Our general tolerance for machined parts in metal is DIN-2768-F standard. For our plastic CNC service, we work to the DIN-2768-M standard

In most cases, we respond within 24 hours after receiving an RFQ. Should any project extend beyond the anticipated timeframe, we'll promptly inform you.

we will sign and adhere to any non-disclosure or confidentiality agreement.We also have a strict policy within our factory that no photographs are ever allowed of a customer’s product without permission

Our lead time—the duration from order placement to delivery—varies based on the project's complexity, order volume, and current production capacity. general projects : 2-3 weeks.For a precise estimate tailored to your specific needs, please contact us directly.

Can't Find Answer? Ask Us.

still have queries about your service or your projects, please contact us : info@kachi-machining.com