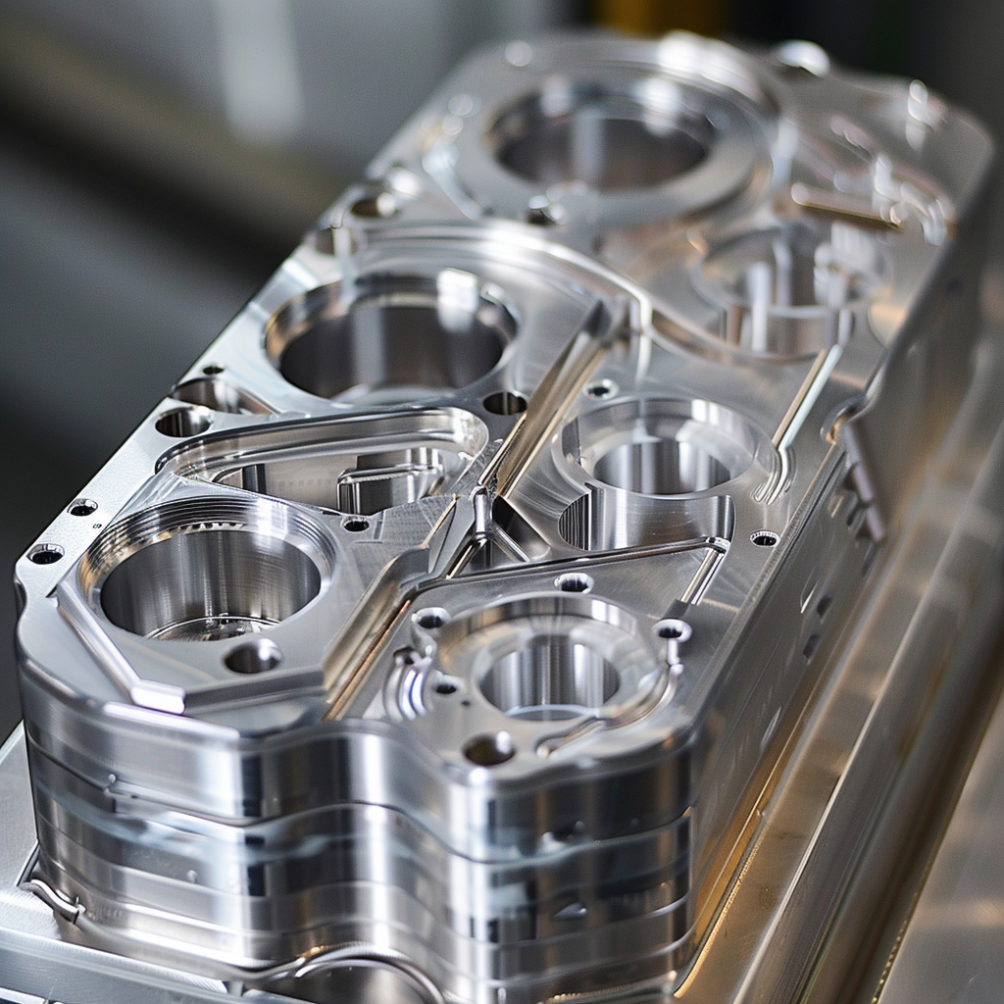

cnc machining parts

CNC machining service for rapid prototypes and production parts in metals or plastics

You trusted partner in cnc machining service

At Kachi, we understand the intricate requirements of automation parts and the critical role they play in your operational efficiency and product reliability

CNC milling excels in producing intricate prismatic shapes and flat surfaces, accommodating an endless array of commercial and industrial applications. With multi-axis metal CNC machines that boast flexibility and precision without the need for fixed tooling, we are equipped to handle your most challenging CNC milling projects, regardless of volume. Discover how we can assist with your demanding requirements.

CNC turning stands out as the optimal solution for creating deep holes, machined threads, and various cylindrical shapes with exceptional surface finishes. For parts requiring precise manufacturing, swift production times, and unrestricted volume capabilities, turning to CNC turning at kachi offers the perfect answer. Discover more about our support capabilities.

For cnc machined parts, we adhere to the DIN-2768-1tolerance level, Given that a part's specific geometry and chosen material can significantly influence tolerances and dimensions, we strongly encourage early consultations with our engineering team for any queries or concerns.

CNC programming is the process of converting a 3D design into machine-readable instructions that control the movements and operations of CNC machines to precisely fabricate parts and products. It is a crucial aspect of automated manufacturing that enables high accuracy, efficiency, and repeatability in the production of complex components across various industries.

the primary input code for CNC machining is a combination of G-codes for motion control and M-codes for auxiliary functions, which can be programmed manually, conversationally, or generated automatically through CAM software. The specific code syntax and commands vary by machine tool and manufacturer.

Elevate Your Project's Success with kachi: Your Partner in Prototyping, Rapid Tooling, and Low-Volume Manufacturing. Our global team of engineering experts collaborates closely with you, transforming your product concepts into tangible results. Leveraging advanced manufacturing technologies such as CNC machining, and comprehensive finishing services, we're here to support every phase of your product development journey

How it works

Customized your projects

tell us your idea, we make your ideas to reality, check how to customize your projects from right side.

Consultation what you need.

upload your requirements & your drawing profile

Design for Manufacturing analisis

Based on the provided sources, Design for Manufacturing (DFM) analysis involves evaluating product designs to ensure they are optimized for ease of manufacturing, cost-effectiveness, and high-quality production

Cost Evaluation

A cost evaluation of CNC machining services involves analyzing various factors that influence the overall price of manufacturing parts using CNC technology

Issue production

Our team starts collaborating to transform your ideas into products

what is cnc machining ?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled machine tools to remove material from a workpiece to create a desired shape or part

The advantage of cnc machining service

The advantages of CNC machining, as highlighted in the provided sources, include:

- Precision: CNC machines can create parts exactly to specification with accuracy up to within thousandths of an inch, eliminating human error common in manual operations2.4

- Repeatability: CNC machines can produce identical parts repeatedly, ensuring consistency and reducing the risk of errors, leading to improved product quality and customer satisfaction.2

- Efficiency: CNC machines operate 24/7, allowing for high-volume production with minimal labor required, resulting in increased efficiency and faster production times2.4

- Flexibility: CNC machines can be programmed to create a wide range of parts, making them ideal for prototyping and short-run production, offering greater flexibility to meet changes in demand.2

- Safety: CNC machines are designed with safety features to protect operators and reduce the risk of accidents, enhancing personnel safety in manufacturing environments.2

- Cost-Effectiveness: CNC machining leads to lower production costs by improving efficiency, scalability of production, reducing material waste, energy consumption, and labor costs while maintaining high quality standards3.4